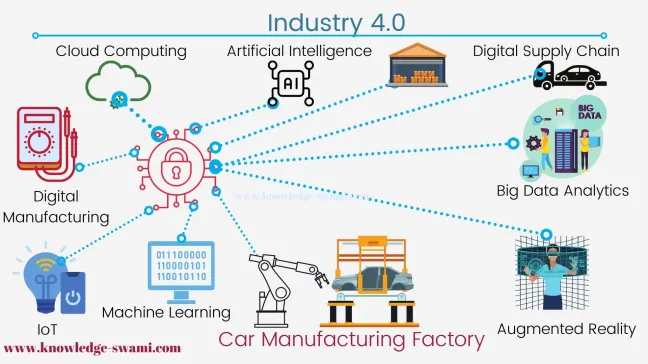

The advent of Industry 4.0 marks a new era in manufacturing, characterized by the integration of advanced technologies like artificial intelligence (AI), the Internet of Things (IoT), big data, and robotics. These technologies are revolutionizing traditional manufacturing processes, leading to the concept of “smart manufacturing.” This article explores the profitable AI applications in Industry 4.0, highlighting how businesses can leverage these innovations to enhance productivity, efficiency, and profitability.

Contents

Understanding Smart Manufacturing and Industry 4.0

Industry 4.0 refers to the fourth industrial revolution, which focuses on the digitization and automation of manufacturing processes. Smart manufacturing, a key component of Industry 4.0, involves the use of AI and other advanced technologies to create intelligent, automated, and interconnected production environments. These technologies enable real-time monitoring, predictive maintenance, and optimized decision-making, transforming how products are designed, produced, and delivered.

Key AI Applications in Smart Manufacturing

Predictive Maintenance:

Predictive maintenance uses AI algorithms to analyze data from sensors and machinery to predict when equipment is likely to fail. This allows manufacturers to perform maintenance only when necessary, reducing downtime and maintenance costs. For example, companies like General Electric and Siemens use AI-driven predictive maintenance to monitor the health of their industrial equipment and optimize maintenance schedules, resulting in significant cost savings and improved operational efficiency.

Quality Control and Defect Detection:

AI-powered computer vision systems can inspect products for defects with high accuracy and speed. These systems use machine learning algorithms to analyze images and identify defects that may be missed by human inspectors. Implementing AI in quality control ensures that products meet the highest standards, reducing waste and increasing customer satisfaction. Companies like IBM and Cognex offer AI-driven quality control solutions that enhance the reliability and efficiency of manufacturing processes.

Supply Chain Optimization:

AI can optimize supply chain operations by analyzing vast amounts of data to predict demand, manage inventory, and streamline logistics. AI algorithms can identify patterns and trends in supply chain data, enabling manufacturers to make informed decisions and respond to market changes swiftly. Amazon and DHL are examples of companies that use AI to optimize their supply chain operations, reducing costs and improving delivery times.

Robotic Process Automation (RPA):

RPA leverages AI to automate repetitive and time-consuming tasks, such as data entry, order processing, and inventory management. By automating these processes, manufacturers can reduce labor costs, minimize errors, and improve productivity. Companies like UiPath and Blue Prism provide RPA solutions that enhance manufacturing efficiency and profitability.

Digital Twins:

A digital twin is a virtual replica of a physical asset, process, or system. AI-driven digital twins can simulate manufacturing processes, predict outcomes, and optimize performance. By creating digital twins of their production lines, manufacturers can test different scenarios, identify bottlenecks, and implement improvements without disrupting actual operations. Siemens and Dassault Systèmes are leaders in the development of digital twin technology, offering solutions that drive innovation and efficiency in manufacturing.

Advanced Analytics and Process Optimization:

AI enables manufacturers to analyze large datasets and extract valuable insights for process optimization. Machine learning algorithms can identify inefficiencies, recommend improvements, and predict the impact of changes on production outcomes. By leveraging AI-driven analytics, manufacturers can enhance their processes, reduce waste, and increase profitability. Companies like Honeywell and Rockwell Automation provide advanced analytics solutions that empower manufacturers to optimize their operations.

Benefits of AI in Smart Manufacturing

Increased Efficiency:

AI-driven automation and optimization enhance the efficiency of manufacturing processes. By reducing manual labor and minimizing errors, manufacturers can achieve higher productivity and lower operational costs.

Enhanced Quality:

AI-powered quality control systems ensure that products meet stringent quality standards, reducing defects and waste. This leads to higher customer satisfaction and improved brand reputation.

Cost Savings:

Predictive maintenance, supply chain optimization, and process automation reduce operational costs and minimize downtime. These cost savings contribute to higher profitability and competitiveness.

Agility and Flexibility:

AI enables manufacturers to respond quickly to market changes and customer demands. By optimizing supply chain operations and production processes, manufacturers can maintain agility and flexibility in a dynamic business environment.

Data-Driven Decision Making:

AI-driven analytics provide manufacturers with valuable insights for informed decision-making. By leveraging data, manufacturers can identify opportunities for improvement, optimize processes, and drive innovation.

Challenges and Considerations

While the benefits of AI in smart manufacturing are substantial, several challenges and considerations must be addressed:

Data Security and Privacy:

The integration of AI and IoT devices in manufacturing generates vast amounts of data. Ensuring the security and privacy of this data is crucial to prevent cyber-attacks and data breaches.

Integration with Legacy Systems:

Integrating AI technologies with existing legacy systems can be complex and costly. Manufacturers need to invest in modernizing their IT infrastructure and ensuring seamless interoperability.

Workforce Training and Adaptation:

The adoption of AI in manufacturing requires a skilled workforce capable of operating and managing advanced technologies. Manufacturers must invest in training and upskilling their employees to fully leverage AI capabilities.

Regulatory Compliance:

Manufacturers must navigate complex regulatory landscapes and ensure compliance with industry standards and regulations. This is particularly important in sectors such as pharmaceuticals and aerospace, where strict quality and safety standards apply.

Scalability and ROI:

Implementing AI solutions at scale requires significant investment. Manufacturers need to carefully evaluate the return on investment (ROI) and ensure that AI initiatives align with their long-term business goals.

The Future of AI in Smart Manufacturing

The future of AI in smart manufacturing is promising, with several exciting developments on the horizon:

Collaborative Robots (Cobots):

Cobots are designed to work alongside human workers, enhancing productivity and safety. AI-driven cobots can perform complex tasks, learn from human interactions, and adapt to changing environments. Companies like Universal Robots and Rethink Robotics are pioneers in the development of cobots, driving innovation in smart manufacturing.

AI-Powered Augmented Reality (AR):

AR technology, powered by AI, can enhance manufacturing processes by providing real-time information and guidance to workers. AR devices can overlay digital information onto the physical world, assisting with tasks such as assembly, maintenance, and quality inspection. Companies like PTC and Microsoft are developing AI-driven AR solutions that enhance productivity and reduce errors.

Sustainable Manufacturing:

AI can contribute to sustainable manufacturing by optimizing energy consumption, reducing waste, and minimizing environmental impact. Manufacturers can use AI to monitor and manage their environmental footprint, ensuring compliance with sustainability goals and regulations.

Hyper-Personalization:

AI enables hyper-personalization in manufacturing, allowing companies to create customized products tailored to individual customer preferences. By leveraging AI-driven analytics and production technologies, manufacturers can offer personalized products at scale, enhancing customer satisfaction and loyalty.

Conclusion

AI is revolutionizing the manufacturing industry, creating profitable applications and innovations that drive efficiency, quality, and profitability. From predictive maintenance and quality control to supply chain optimization and digital twins, AI is transforming how products are designed, produced, and delivered. While challenges such as data security, integration, and workforce training must be addressed, the future of AI in smart manufacturing is full of promise. As AI technologies continue to evolve, they will undoubtedly unlock new possibilities and reshape the manufacturing landscape for years to come.